Landing On Mars In One Piece

- No Comments

Spacecraft Decelerator Testing

Spacecraft Decelerator Testing

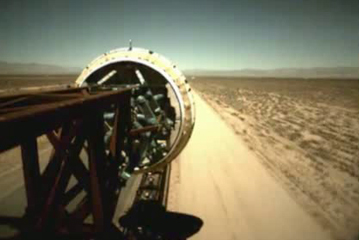

Long before NASA’s Perseverance Rover landed on Mars years of prototyping and testing was first completed here on Earth. Mega Speed high speed Gforce cameras were used during the initial testing and verification of the decelerator designs intended to decelerate Perseverance Rover’s high velocity space craft before landing on Mars. High speed image data was needed during the critical testing of various decelerator designs that included inflatable decelerators as well as large parachute decelerators. It would be absolutely critical that the decelerator design be able to slow the space craft down sufficiently in Mars very thin atmosphere for a safe landing.Various Mega Speed camera models were used during these tests. Model selection was based on the test environment and the recording requirements of each individual test. Hi Gforce cameras were mounted on the rockets sleds used to propel the test items down the supersonic test track. Other camera models were used on track-side flight followers to record the test item as it passed by. Rocket sled testing was required to accelerate the test items to a high enough velocity to simulate the re-entry speed that the spacecraft would experience while attempting to land on Mars.

The above frames have been removed from the actual high speed test video from the test video related to the Mars missions.

High speed video slows time down to reveal what otherwise would be impossible to see with standard video.

Recommend Posts

Mega Speed software solutions

- No Comments

Keeping our high-speed customers productive

Mega Speed software solutions keep our high-speed customers productive

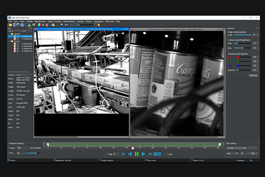

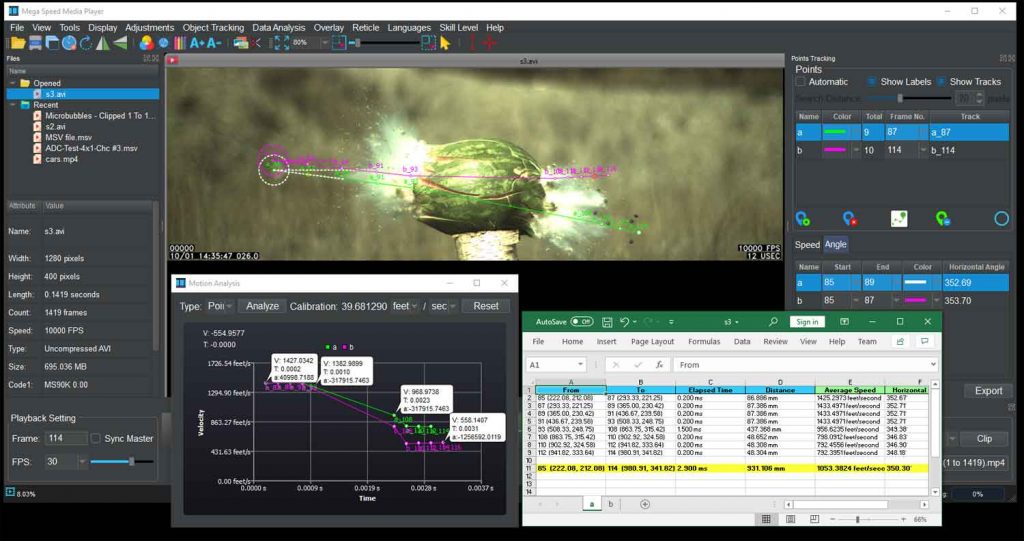

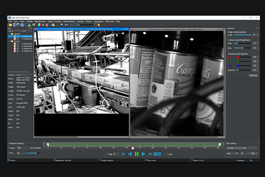

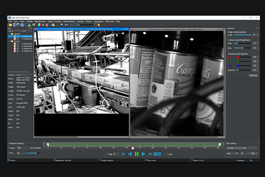

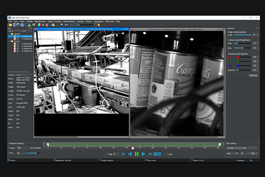

Mega Speed’s Media Player and Camera Control software is a feature-rich software platform that ships with every high-speed camera that we sell. The tools within our software allow the end-user the ability to measure, synchronize, batch process, clip, and compress their high-speed video files. These innovative software tools offer our customers some of the best video analyzing workflows available. Mega Speed’s software solutions help you make sense of your high-speed image data.

The above picture is a screenshot of the Mega Speed Media player while the end-user is calculating velocities and angles.

Recommend Posts

Aviation Flight Safety

- No Comments

Feel Safer

While Flying During

Inclement Weather

Mega Speed DVR recorders are helping to keep you safe while flying during inclement weather

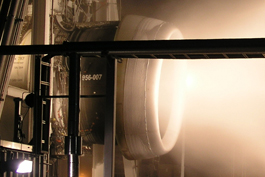

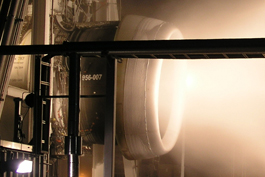

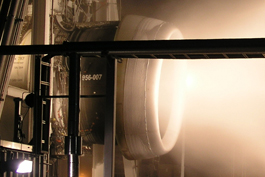

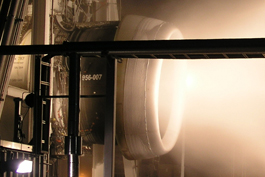

A great deal of testing and certification is required before an airplane’s jet engines are certified to fly. For the past 15 years, many of the Jet engines in service today have been ice accretion tested with Mega Speed’s high-speed DVR cameras and recorders. Ice accretion is the process where ice begins to form on the aircraft’s jet engines and wings while flying through freezing precipitation or supercooled fog. Ice accretion testing is conducted in a test facility during the winter months when conditions are favorable for ice accretion.

The above picture is an aerial view of an ice accretion test facility.

Recommend Posts

Trouble-Shooting High Speed Production Lines

- No Comments

Trouble-Shooting

High Speed

Production Lines

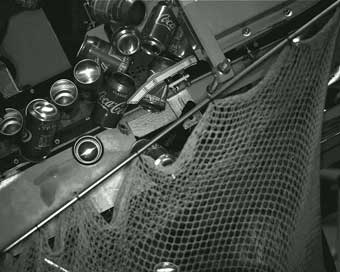

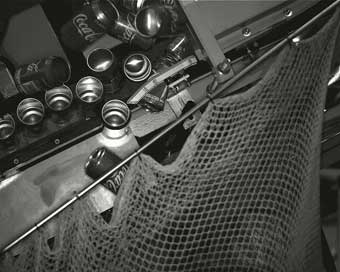

Trouble-Shooting High Speed Production Lines

The above 6 picture set of frames have been removed from the actual high-speed diagnostic video to show the pile-up of cans while the line was being brought up to speed. The high-speed video slows time down to reveal what otherwise would be impossible to see with standard video or the unaided human eye.

Recommend Posts

Destructive Impact Testing

- No Comments

Destructive Impact

Testing

Destructive Impact Testing

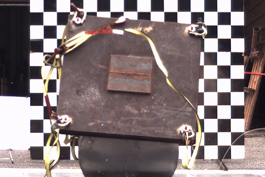

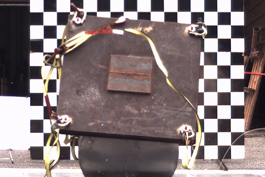

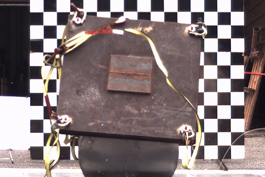

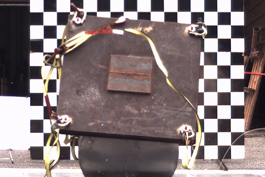

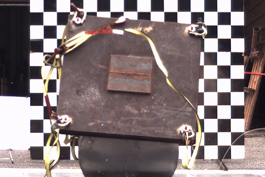

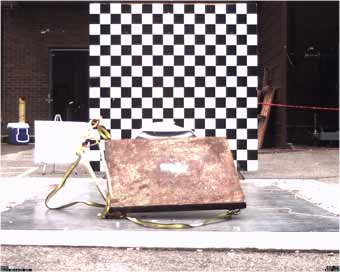

Mega Speed high-speed impact test cameras are used by accredited government test agencies and private accredited test labs during critical component design and testing. One example application is the destructive testing of steel storage drums, which are used to store nuclear waste. A heavy steel plate is dropped onto the test article while being recorded with a Mega Speed high-speed impact test camera.

The above 6 picture set of frames have been removed from the actual high-speed test video to show how the structure of the steel drum performed on a millisecond time scale after a heavy steel plate was dropped on it.

Recommend Posts

Helping To Keep You And Your Loved Ones Safe

- No Comments

Helping To Keep

You And Your

Loved Ones Safe

Helping To Keep You And Your Loved Ones Safe

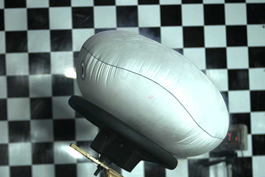

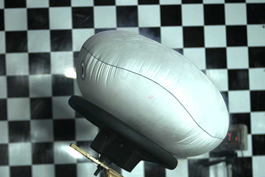

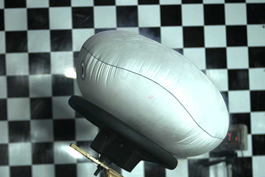

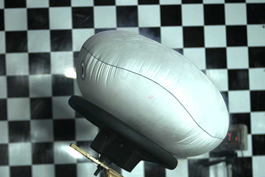

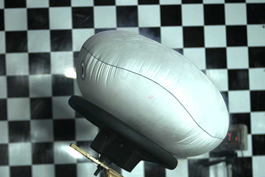

Mega Speed’s high-speed cameras are used by some of the world’s most well-known car manufacturers and component makers during critical component design and testing. One case in point is one of your automobile’s top safety features namely the airbag. The airbags in your vehicle need to precisely inflate and deflate correctly and with the correct shape to cushion your body from hitting parts of your vehicle’s interior. In order to correctly test an airbag to perform its critical life-saving task, a precise analysis must be performed during the bag’s inflation/deflation cycle.

The above 8 picture set of frames have been removed from the actual high-speed test video to show the rapidly evolving shape of the airbag on a millisecond time scale after the initial inflation was started. The high-speed video slows time down to reveal what otherwise would be impossible to see with standard video.

Recommend Posts